Our kit bag and it's development

The development of our new optometrist kit bag has been an exciting journey, involving a dedicated team of two who worked tirelessly to create a lightweight and efficient solution for our optometrists.

Let’s dive into the details of this remarkable project by speaking to the core team behind the development of the new kit bag - Regional Manager, Dan Young and Senior Designer, Jon Richards.

OC: Hi Guys, thanks for helping us understand the journey of this innovative design! How did it all come about?

Dan: The project officially commenced in January 2021 after we received feedback from optometrists indicating that the weight of the current bags (over 10kg) was burdensome and hindered their efficiency. Additionally, the existing bag design required unpacking everything, leading to potential equipment being left behind during testing. We also wanted to reduce equipment damage. I was committed to address these concerns and find a way that our colleagues could work more efficiently.

OC: It’s great that your listened to your colleagues and tried to find a solution. How did you go about starting the project?

Dan: The process of creating the new bag was a complicated one, involving several prototypes. Initially the concept involved a case with drawers for easy access to equipment. However, the weight and reinforcement required for the drawers resulted in a final product weighing over 15kg – not the direction we wanted to be going in. It was also inconvenient to carry. It was disheartening as each prototype took up a lot of time so I decided to get some fresh and creative eyes by reaching out to Jon.

Jon: Dan had already done a lot of work and effort to reduce the bag’s size, but it was just the weight that remained an issue due to the built-in drawers. As a newcomer to the project, I was able to provide a fresh perspective.

OC: Its sounds like a lot of hard work went into those initial ideas, what were the next steps once you both got your heads together on the project?

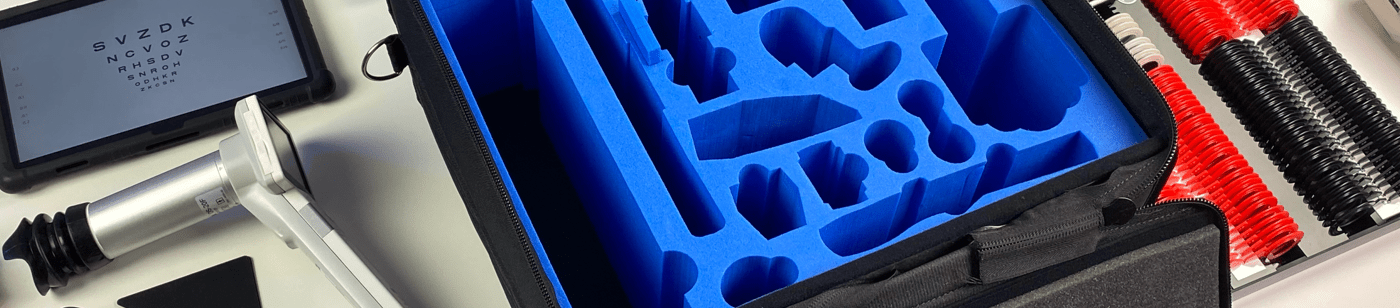

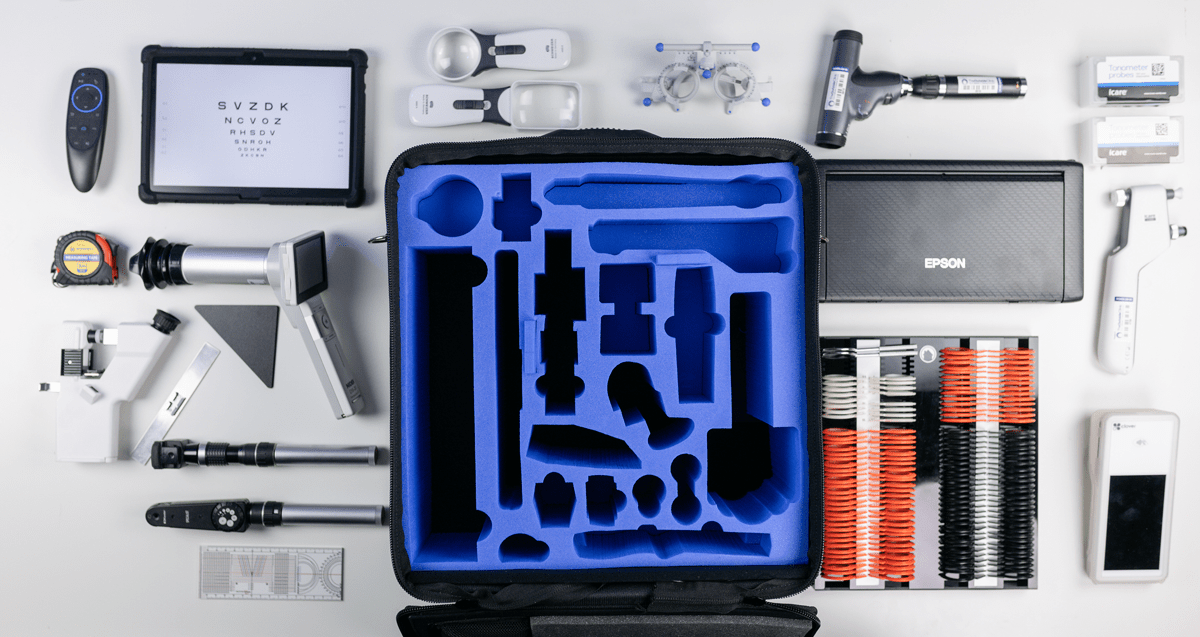

Jon: First of all, we examined the frames case that the kit bag was intended to sit on top of, determining the ideal size for seamless integration. Next, we laid out all the necessary equipment to understand the absolute minimum size we could achieve. Fortunately for us, this fit within our target bag dimensions, but then real challenge began designing the bag's interior to accommodate all the equipment.

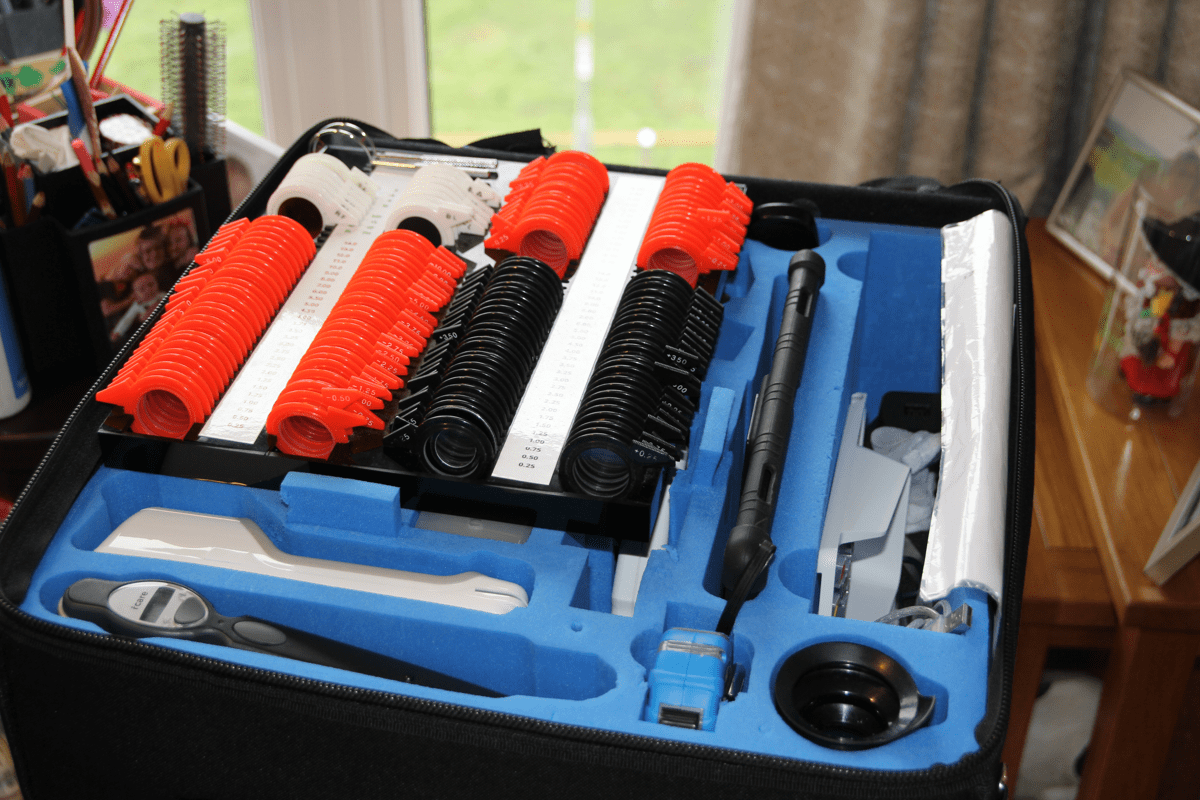

Our breakthrough moment came when we decided to turn the case on its side, which allowed us to view it from a different angle. We then used Blu Tac to stand up all the equipment shorter than the bag's height, exploring the idea of a foam block within the bag that would hold each piece securely. By arranging the items vertically, we found that the awkwardly shaped equipment fit better, providing improved access as well.

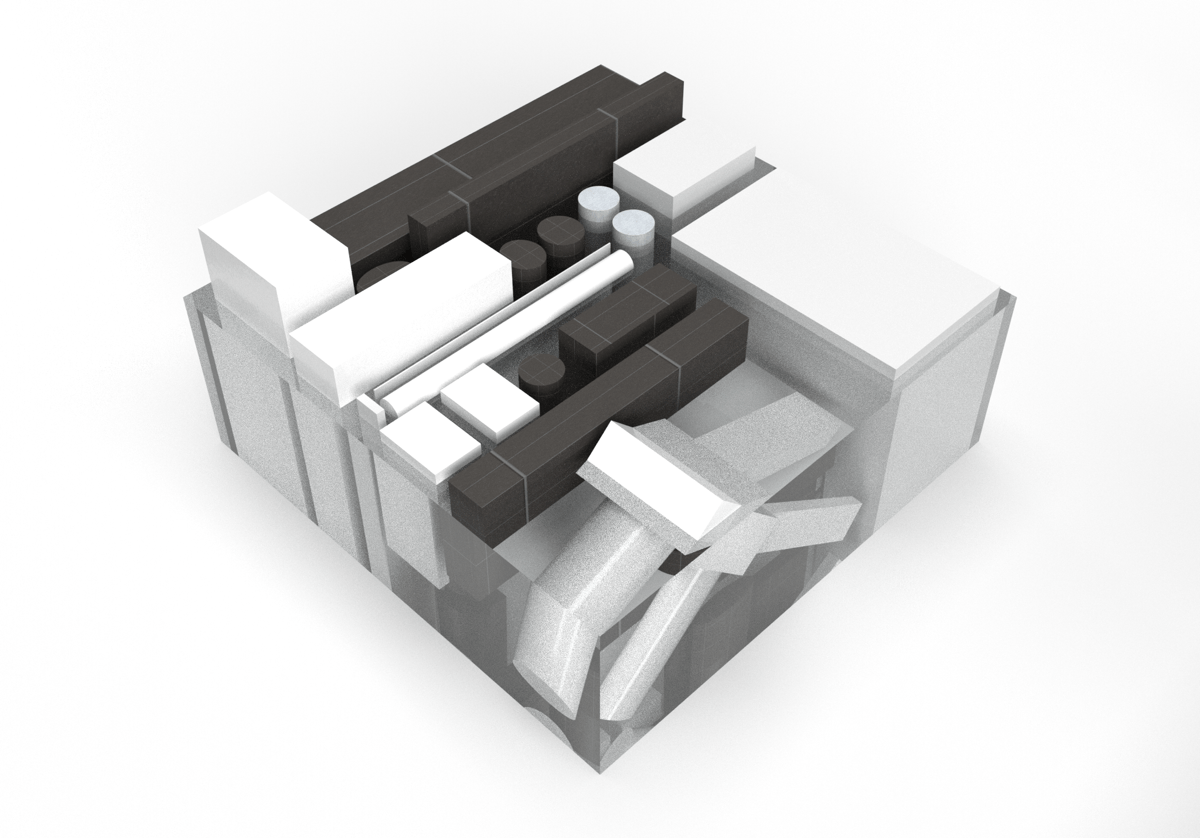

With this new approach in mind, I measured each piece of equipment and created rough 3D models in software, enabling us to experiment with various configurations until everything fit. Once we had a workable mock-up, Dan sent it to the manufacturing company to produce the foam block for the equipment.

The end design meant that the lens tray now sits on top of the bag, with a foam insert in the lid to hold the lenses securely during transportation. We also left some extra space for customisation, allowing users to include additional accessories or a portable printer, depending on their preference.

Dan: Once we got to this point, I continued to fine-tune the design with the manufacturers, adding features such as a handle cut out to prevent it from hitting your hand and extra pockets for documentation.

OC: Wow! What a creation! What are the main benefits for the optometrists with the new kit bag?

Dan: The difference between the old and new bags are substantial. The previous bag weighed over 10kg, while the new one weights just 6.4kg. This significant reduction in weight has had a tremendous impact on our optometrists. They appreciate the lighter load, as it enables them to streamline their testing process, see more patients in a day, and reduce physical strain. Additionally the new bag has led to reduced damage to equipment, leading to cost savings and a longer lifespan of our tools. The new bag also serves as a branding opportunity, effectively promoting our company image.

OC: You got there in the end, and it’s a fantastic invention! You should be proud of yourselves. Where are we at with the new kit bag now?

Dan: At present, we have successfully deployed the new kit bags to over 70 optometrists. The rollout is expected to be completed by the end of July, ensuring all optometrists have access to the improved equipment. Any old bags that are returned in good condition are given away to individuals who expressed interest in acquiring them. We aim to repurpose the bags and minimise waste.

OC: Fantastic news! How was it working together on this project?

Dan: It’s been great working with Jon! He is a creative mind and getting his perspective was really helpful and enabled us create something that really benefits the company.

Jon: It’s been great, I don’t often get the chance to work with Dan on many projects, but this is a true testament to the power of fresh perspectives, creative problem-solving and collaboration in bringing a truly revolutionary product to life.